RAPID® FT CS

Best technical values - ideal for metal-wood connections

Fullthread, °90 countersunk head

Ø 8.0 x 120 to 600 mm

Ø 10.0 x 120 to 1000 mm

Ø 12.0 x 200 to 1000 mm

Features

Countersunk head with milling ribs

- Reduce tearing and splitting in the wood

- Reduced splitting of the wood

- Fits perfectly into metal parts

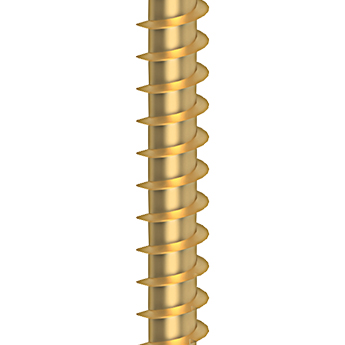

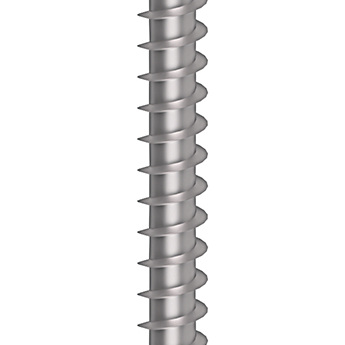

Thread geometry

- Constantly low torque due to anti-friction coating

- Excellent thread pull-out values

- Excellent pressure values

- Maximum load-bearing capacity

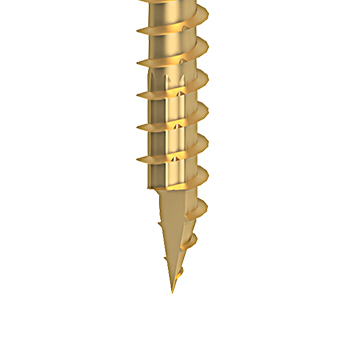

Patented tip - no pre-drilling necessary!

- Self-drilling tip with ridged core

- Minimised splitting

- 50percent lower screw-in torgue

Accessories

The RAPID® Secure screw-in tool enables long timber construction screws to be screwed in securely, easily and quickly.

Applications: RAPID® fullthread

In timber to timber connections, RAPID® fullthread screws are only used in a few cases as normal to the component joint in shear. They are predominantly used as inclined fasteners subjected to axial tension or compression.

Screw crosses can be arranged for general load directions. Other applications include component reinforcements for transverse tensile stresses or high shear stresses.

In the group of metal to timber connections, RAPID® fullthread screws in conjunction with support plates enable a significant increase in the load-bearing capacity of the timber component subjected to transverse compressive stress in the support area.

Cross Laminated Timber (Ceiling Rib)

Shear-resistant crosswise screwing for cross laminated timber ceilings.

Tip: the connection should first be pulled tightly together using e.g., partial thread screws. The pitch of the screws should be oriented in the direction of the main load.

Reinforcement of openings with long RAPID® fullthread screws

The area marked in red indicates the risk of cracking. The same thread length is required above and below this marking. Long full thread screws with cylinder heads are recommended. They can be positioned exactly using long bits.

Transverse tension reinforcement for notching

The structural engineer must review the requirement. If the transverse tensile load is too high for the timber section, full thread screws will be used to reinforce and secure the beam in the red line area.

Support reinforcement with steel plate and fullthread screws

RAPID® fullthread screws transfer the support load from the timber section directly to the steel plate through the screw heads. They distribute the force evenly into the end grain of the support.