The fact that your products have special value starts with the fact that you have special ideas in your production. Ideas that we implement for you precisely and to a high standard in terms of technology. Competently planned and designed, manufactured from first-class materials on modern equipment: What Schmid Schrauben produces works.

TOP - Advice

In the beginning, there is a necessity. Then an idea. Then a sketch and at some point a precise construction drawing. Wherever you stand: We pick you up right there. We discuss your ideas or wishes with you, and not only as a toolmaker. We work together with you as production optimisers. After all, that is what it′s all about.

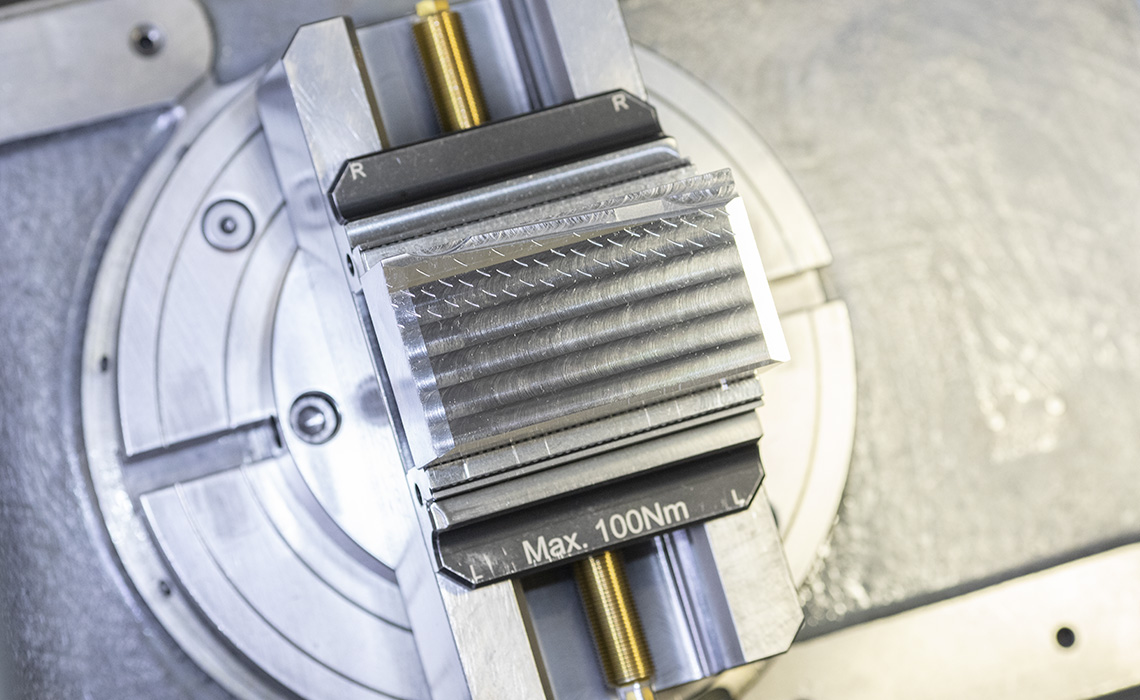

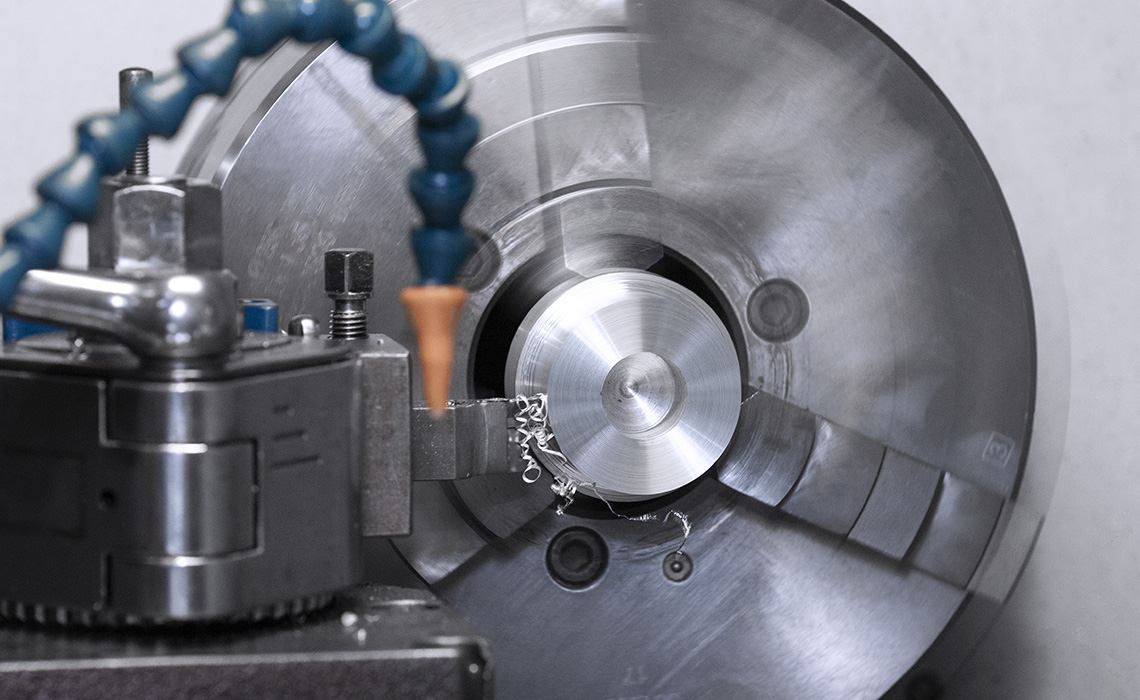

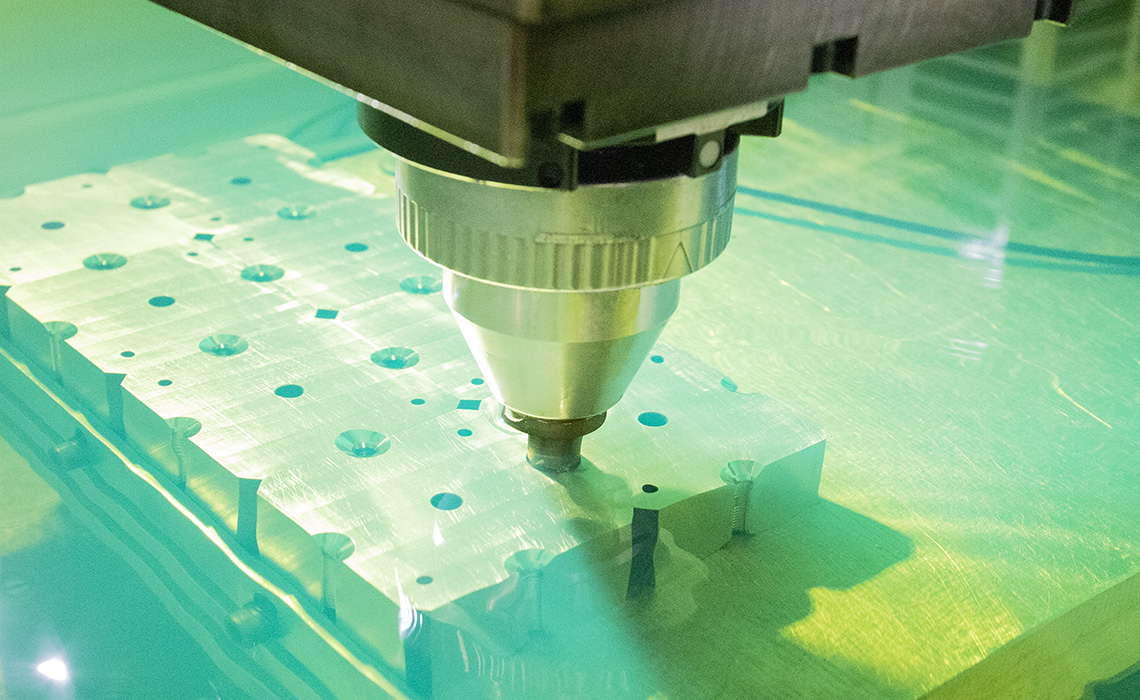

TOP - Technology

Functionally reliable

Competent

Process-Optimised

Practicality

3D-Printing

Where the possibilities of conventional production end, we offer additional production possibilities with our 3D printers for metal and plastic.

Metal printing is perfectly suited for the production of complex metallic individual parts, and also for prototypes as a preliminary stage to series production at our plant.

We offer the printing of transferred components on the one hand, and component optimization and redesign on the other. We are happy to prepare your 3D file for 3D printing.