Wholesalers

Power of supply

We deliver where others order

Whatever kind of screws you need, we produce them in next to no time: With our own wire drawing plant and tool production, we don’t need to wait for any preliminary suppliers. And you save storage costs: Because we don’t just delivery fast, but also absolutely reliably.

European standards

With Schmid Schrauben from Austria you rely on added value instead of on price and quality dumping: With superior technology according to ETA (European Technical Approval). And with environmentally and socially compatible production (ISO 14001, ISO 50001).

Your screw, your brand

Combine your screws inseparably with your quality standard and your name: We supply you with individual labels and boxes and on request, we even give the screw itself your unmistakable design logo.

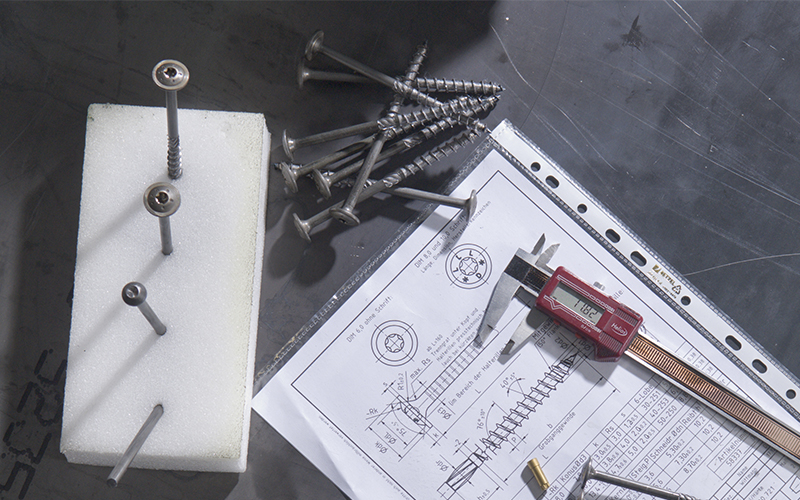

We will accompany you personally during the development of your custom screw or non-screw connection. When entering new areas of fastening technology together, we thoroughly test the result by means of initial samples and prototypes. This saves you and your customers all risks and provides planning reliability for your production.

Production

We make your custom fastening elements at the high quality you expect from Schmid Schrauben and supply (and store) them as flexible as ever.

Reliable know-how protection

For us, the know-how you invest in your custom-made fastening technology is a substantial value base. Just like you: That’s why we optimally protect it and treat it with corresponding discretion.

Custom refinement

Choose from many different refinement options

Galvanising protects your screw or fastening element from corrosion. The zinc coat itself, however, is exposed to white rust over time. Using expertly applied after-treatments such as a chrome coating, the formation of white rust can be delayed.

Thick-film passivation: Thick-film passivation can be used to achieve higher corrosion resistance. It can also be used to create many different colours, such as pink.

Chrome coating is a step most often performed after galvanising. If possible, we prefer chromium VI free coatings that are non-damaging to health and environment.

Transparent chrome coating

Free of chromium VI, but provides only limited corrosion protection.

Blue chrome coating

Available with or without chromium VI. Light blue hue, weak corrosion protection.

Yellow chrome coating

A popular choice thanks to its good and relatively cost efficient corrosion protection. However, this product is no longer approved for all applications due to its chromium VI content. Often the colour appears irregular.

Black chrome coating

Medium corrosion protection, available with and without chromium VI.

The screws can be painted to match the colour of their surroundings. All RAL colours are possible.

Custom packaging

With many different versions to choose from – from boxes made from environmentally friendly natural cardboard to plastic bags – and with intelligent and user-friendly designs, Schmid Schrauben packaging conveys sustainable quality and customer-orientation. Individual packaging design / your logo printed on make every Schmid screw your screw and turn Schmid Schrauben’s quality advantage into your quality advantage.

- Various folding options are available (opening type, with/without chute)

- Environmentally friendly – print an environmental protection label onto your packaging

- Your individual print – colour and layout tailored to your requirements

- Labels tailored to your requirements

Wood processing companies

Timber construction stands for an environmentally conscious construction method since wood is a raw material that always grows back. Additionally, timber buildings wow with extraordinary energy efficiency during their life cycle.

Schmid Schrauben helps your wood-processing company fulfilling your customers’ wishes with high-quality products. We supply crews for structural timber construction, glulam construction, multi-storey timber construction, custom constructions etc. Drawing on more than 180 years of fastening technology experience, your timber construction company can rely on our knowledge.

Sustainability and the environment

Once a timber building has reached the end of its life cycle our screws can be cleanly removed, thus allowing girders and beams to be reused.

Our premium products allow you to realise more efficient user solutions with fewer screws, saving resources

Timely and reliable delivery

Failing to meet delivery deadlines makes customers lose their trust. We make sure your materials are always delivered on time, if needed directly to the construction site.

Given sufficient time to prepare, we produce individual fastening solutions just for you and deliver them within the specified deadlines.

Customer friendly

Let your customers take it easy

Whether ready to hand in target group-specific quantities as packaged goods or loose with clearly defined guide colours for self-service scales: quality in screw sales doesn′t have to be complicated.

Cost friendly

The handle-by-handle self-service system for EAN-coded Schmid screws makes it easy for your customers and economical for you: you save costs because you save space and personnel.